Nylon Spandex Fabric: Risk Management

Introduction

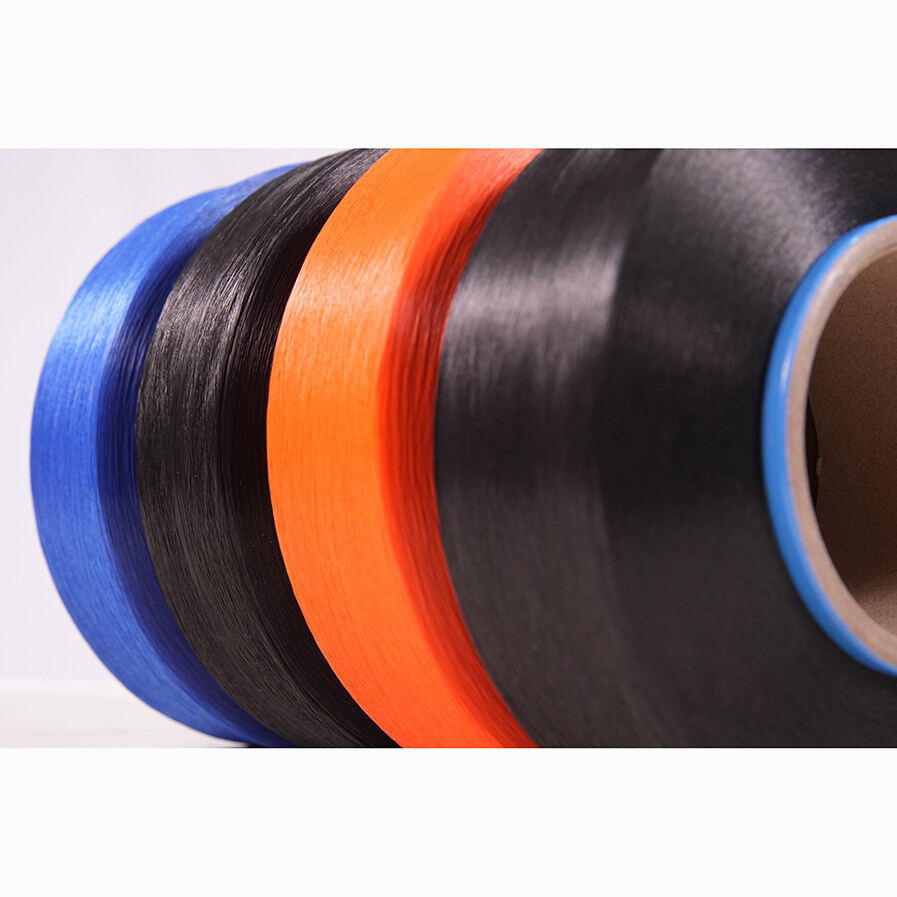

Nylon spandex fabric manufacturing stands at the nexus of innovation and demand, catering to a diverse range of industries from apparel to medical textiles. However, amidst the dynamic landscape of global trade and market fluctuations, the industry faces inherent risks that can disrupt operations and profitability. In this article, we delve into the strategies employed by manufacturers to mitigate risks and ensure stability in the manufacturing process of nylon spandex fabric.

Understanding Risks in Nylon Spandex Fabric Manufacturing

Risks in manufacturing are multifaceted, encompassing factors such as supply chain disruptions, fluctuating market conditions, and geopolitical uncertainties. In the context of nylon spandex fabric manufacturing, these risks are amplified due to the complex nature of the production process and the reliance on global supply chains.

Supply chain management emerges as a critical aspect of risk mitigation. Manufacturers adopt strategies such as diversification of suppliers, just-in-time inventory management, and proactive collaboration to minimize the impact of disruptions. By maintaining a network of reliable suppliers and optimizing inventory levels, manufacturers can mitigate the risks associated with raw material shortages or logistical challenges.

Market analysis and forecasting play a pivotal role in anticipating and responding to fluctuating market conditions. Through rigorous market research and analysis, manufacturers can identify emerging trends and adjust production accordingly. Establishing strategic partnerships with distributors and retailers enables manufacturers to adapt swiftly to changing demand dynamics, thereby reducing the risk of inventory obsolescence or surplus.

Geopolitical risk assessment is essential for navigating the complexities of global trade. Political instability in key sourcing regions or trade disputes can significantly impact the supply chain. Manufacturers proactively monitor geopolitical developments and develop contingency plans for alternative sourcing options. Compliance with international trade regulations and tariffs further mitigates the risk of regulatory disruptions.

Strategies for Mitigating Risks

Supply Chain Management: Diversification of suppliers, just-in-time inventory management, and collaboration with suppliers.

Market Analysis and Forecasting: Rigorous market research, flexible production capabilities, and strategic partnerships.

Geopolitical Risk Assessment: Monitoring political instability, developing contingency plans, and compliance with trade regulations.

Contingency Planning

Scenario planning involves identifying potential risk scenarios and developing response plans. Regular testing and updating of contingency plans ensure readiness to tackle unforeseen challenges.

Business continuity planning focuses on establishing backup production facilities or suppliers, cross-training employees, and investing in resilient infrastructure and technology.

Integration of Risk Management into Organizational Culture

Leadership and Governance: Clear roles and responsibilities for risk management, fostering transparency, and accountability.

Employee Training and Awareness: Providing training on risk identification and mitigation and encouraging prompt reporting of potential risks.

Continuous Improvement: Regular reviews and evaluations of risk management processes, incorporating lessons learned from past incidents.

Conclusion

In conclusion, effective risk management is paramount for ensuring stability and resilience in nylon and spandex fabric manufacturing. By adopting proactive strategies to mitigate risks and incorporating risk management into the organizational culture, manufacturers can navigate uncertainties and sustain competitiveness in a dynamic market environment. Embracing innovation and fostering collaboration across the supply chain are essential for thriving amidst challenges and seizing opportunities for growth.