Para-Aramid Yarn: Composition, Properties, Applications

Introduction

Para-aramid yarn stands as a remarkable achievement in material science, offering a combination of properties that make it indispensable across various industries. From aerospace engineering to everyday protective gear, para-aramid yarn plays a crucial role. In this article, we will delve into the composition, unique properties, and applications of para-aramid yarn, shedding light on its importance in modern manufacturing.

Definition and Overview

Para-aramid yarn, often referred to simply as aramid yarn, is a synthetic fiber renowned for its exceptional strength and heat resistance. It belongs to the family of aromatic polyamides and is distinctively characterized by its rigid molecular structure, which contributes to its remarkable mechanical properties.

Originally developed in the 1960s, para-aramid yarn has undergone significant advancements in manufacturing techniques, resulting in improved performance and versatility. Its widespread adoption across industries is a testament to its reliability and effectiveness in various applications.

Composition of Para-Aramid Yarn

The molecular structure of para-aramid yarn is intricately designed, comprising long-chain polymer molecules with repeating aromatic units. This molecular arrangement grants para-aramid yarn its characteristic strength and rigidity.

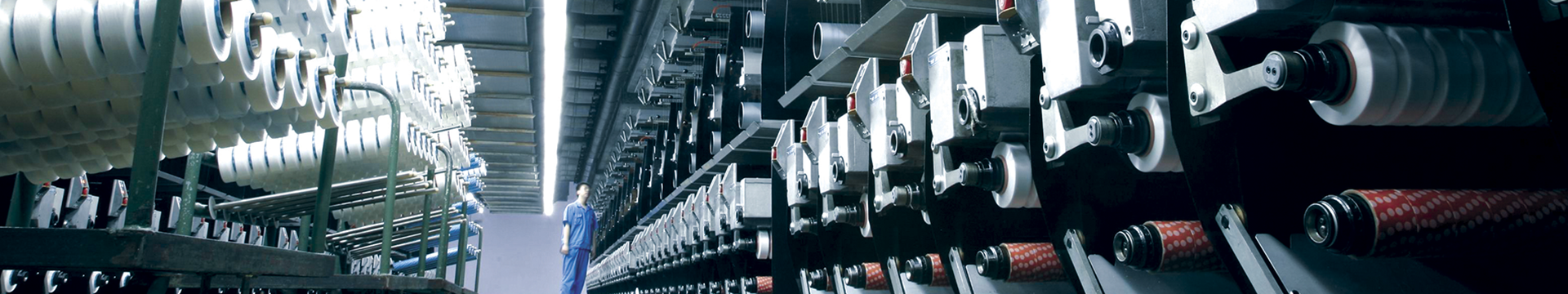

Raw materials used in the production of para-aramid yarn typically include aromatic diamines and aromatic diacid chlorides. These monomers undergo a polymerization process to form the polymer chains, which are then spun into yarn using specialized techniques such as gel spinning or dry-jet wet spinning.

The manufacturing process of para-aramid yarn involves precise control over parameters such as temperature, pressure, and polymer concentration to ensure the desired mechanical properties are achieved.

Unique Properties of Para-Aramid Yarn

Para-aramid yarn exhibits a host of unique properties that set it apart from conventional textile fibers:

1. High Strength: Para-aramid yarn boasts exceptional tensile strength, making it several times stronger than steel on a weight-for-weight basis. This property makes it ideal for applications requiring robust materials, such as ballistic armor and reinforcement fabrics.

2. Heat Resistance: With a high melting point and excellent thermal stability, para-aramid yarn can withstand extreme temperatures without compromising its structural integrity. This property makes it suitable for use in environments with elevated temperatures, such as aerospace components and firefighter gear.

3. Chemical Resistance: Para-aramid yarn demonstrates remarkable resistance to a wide range of chemicals, including acids, bases, and organic solvents. This makes it invaluable in applications where exposure to corrosive substances is a concern, such as industrial filtration systems and chemical protective clothing.

4. Low Flammability: Unlike many other synthetic fibers, para-aramid yarn exhibits low flammability and is inherently flame-resistant. This property makes it a preferred choice for flame-retardant textiles used in firefighting gear and industrial applications where fire safety is paramount.

5. Lightweight Nature: Despite its exceptional strength and durability, para-aramid yarn is remarkably lightweight, making it comfortable for use in applications where weight reduction is critical, such as aerospace components and lightweight body armor.

Comparison with Other Yarn Types

In comparison to other textile fibers, para-aramid yarn offers several distinct advantages:

1. Comparison with Nylon Yarn: While nylon yarn offers good strength and elasticity, it lacks the heat and chemical resistance of para-aramid yarn, making it unsuitable for high-temperature and harsh chemical environments.

2. Comparison with Polyester Yarn: Polyester yarn is known for its affordability and versatility, but it falls short in terms of strength and heat resistance when compared to para-aramid yarn.

3. Comparison with Carbon Fiber Yarn: Carbon fiber yarn exhibits exceptional strength and stiffness but is more brittle and expensive than para-aramid yarn. Additionally, carbon fiber is electrically conductive, whereas para-aramid yarn is non-conductive, making it suitable for applications requiring electrical insulation.

Conclusion

In conclusion, para-aramid yarn stands as a remarkable feat of engineering, offering a unique combination of properties that make it indispensable across a wide range of industries. From its high strength and heat resistance to its chemical inertness and low flammability, para-aramid yarn continues to revolutionize the way we approach material design and manufacturing. As technology advances and new applications emerge, the role of para-aramid yarn is poised to expand further, shaping the future of materials science and engineering.